Introduction

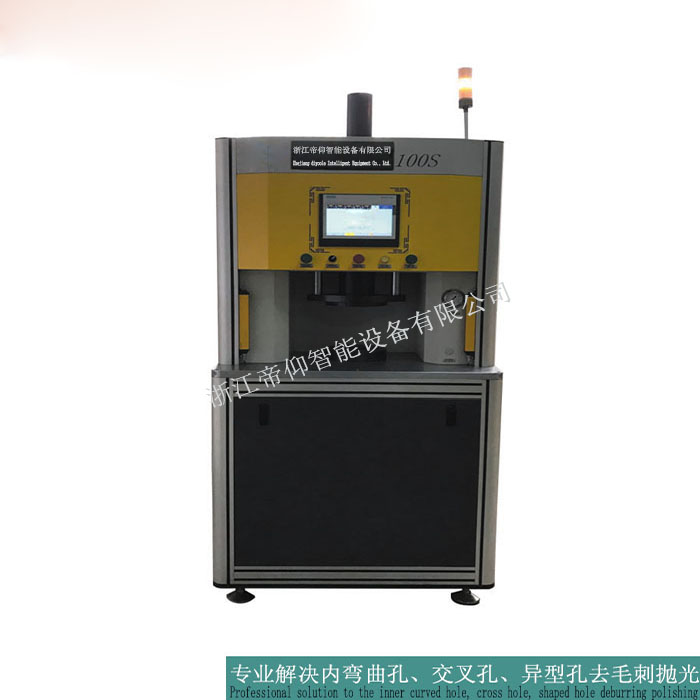

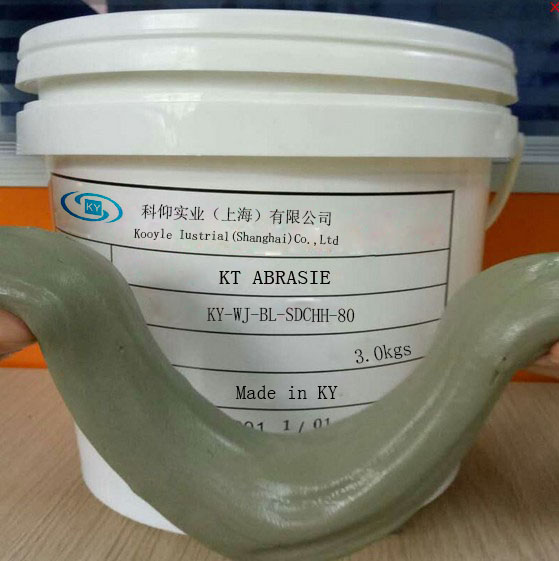

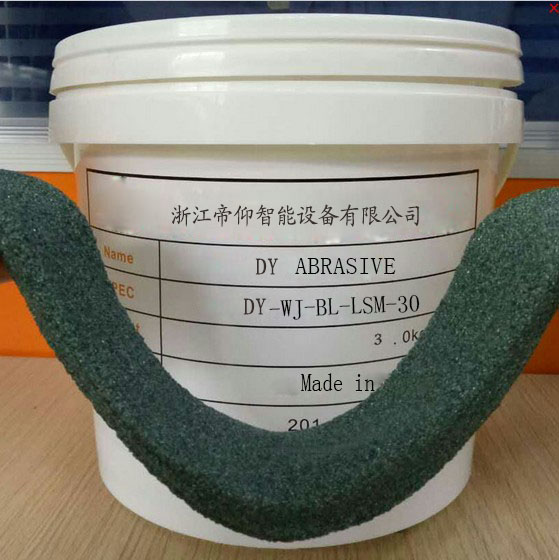

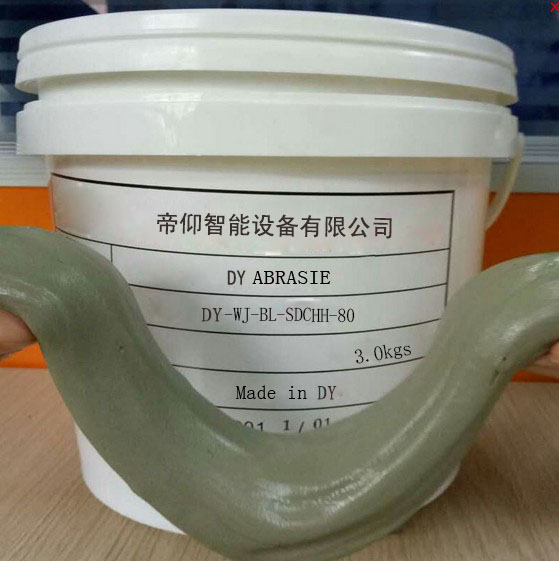

Abrasive Flow Machining works by the back and forth flow under pressure of an abrasive laden, viscoelastic compound or abrasive media, through a holding fixture and over the area to be polished, deburred and radiused. In a typical, two-way flow process, two vertically opposed cylinders extrude the abrasive media back and forth through passages formed by the workpiece and tooling. The soft abrasive flow material which called media base, is a viscoelastic semi-solid, soft material forced through the workpiece surface,blend internal surface passages, inner hole or the end angle, remove burrs, polish surfaces, form radii, chamfering and polishing or grinding, and to get mirror surface by two-way flow process.

This processing is the most suitable for the the complex shape,interior surfaces, slots, holes, cavities, and other areas which usual cutting tools can not reach. is the most suitable processing method.

Especially for mirror polish to those gas or liquid passages,The pressure exerted by the fluid on all contacting surfaces results in a very uniform finish, which grinding marks are consistent with fluid pass direction . It can effectively improve the performance, quality and clean of the work piece to reach the mirror level, and prolong the service life

The surface roughness after polishing can reach Ra0.025-Ra0.04μm.

Machine is customized for more question please contact service hot line 17807521585、17721225073

More Products